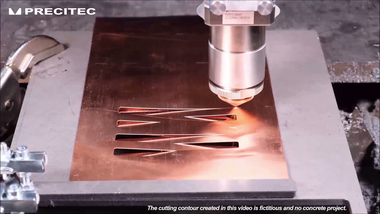

Efficient flatbed cutting for your laser cutting system

2D laser cutting enables a variety of tasks with high quality

Flatbed cutting, also known as 2D cutting, is the most common application in laser cutting. Fiber lasers have established themselves worldwide as the dominant laser beam source. 2D laser cutting systems process flat material of various thicknesses made of steel, stainless steel, aluminium, or non-ferrous metals with great accuracy and high cutting speed. Machines which are used for laser cutting are equipped with a total of three axes: two positioning axes for traversing the desired cutting contour and a Z-axis for adjusting the distance between the workpiece and the cutting head.

Precitec offers high-quality tailor-made solutions for all requirements and machine concepts in 2D laser cutting and has gained worldwide recognition as the market leader in cutting optics, distance sensor technology, and process monitoring.

Typical applications in 2D laser cutting

In 2D laser cutting of thin sheets, high cutting speeds of over 140 m/min and accelerations of up to 6 g are achieved. Precitec cutting heads set the industry standard and continue to convince by providing stable operation, leading to lower operating costs for a fast return on investment.

Fusion cutting of stainless steel and aluminum up to a thickness of 130 mm as well as the flame cutting of mild steel up to 200 mm can be processed under special conditions (high laser power). These sheet thicknesses were previously reserved for plasma or oxyfuel cutting. Precitec's laser cutting heads meet all the necessary requirements for this: from power stability to the changeable adjustment range of the focus position and integrated process monitoring.

ProCutter Thunder – Economical laser cutting in the medium power range

The ProCutter Thunder is the ideal solution for efficient and economical laser cutting in the medium power range. The cutting head shows its advantages to the full on systems for flatbed or bevel cutting: It offers permanently stable and precise operation. The highly dynamic drive stands for minimum non-productive times and flexibility. This regulates the focus position fully automatically and delivers excellent results when processing different material thicknesses. In addition, quick and easy maintenance of the head is possible.

Strong – stronger – ProCutter 85 kW

The powerful ProCutter 2.0 can be operated with up to 85 kW laser power and offers its usual extensive functionality and flexibility. It ensures high dynamics with thin material thicknesses and best quality with thick materials. Especially for flatbed, tube cutting, and laser blanking systems, the potential of the cutting head is optimally converted into productivity.