Precision and efficiency for 2D, 2.5D and 3D laser cutting

Innovative solutions for the highest demands

Whether in series production or for special applications - Precitec offers customized solutions for 2D, 2.5D and 3D laser cutting. Our highly developed cutting heads and intelligent process sensors ensure maximum process reliability, the highest cutting quality and efficient production.

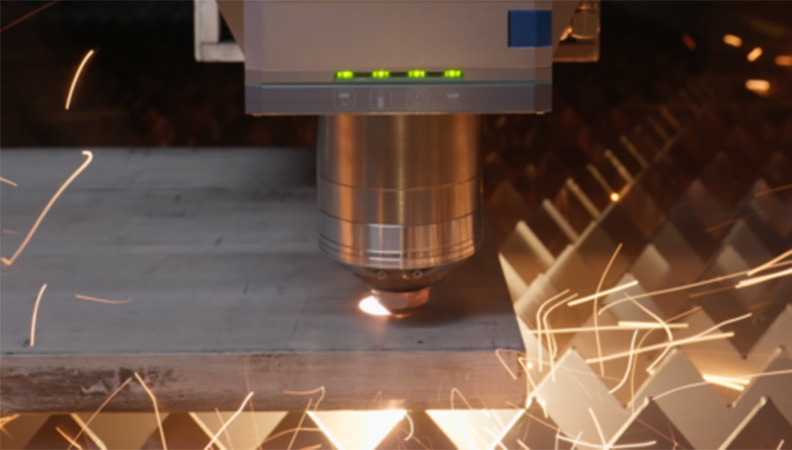

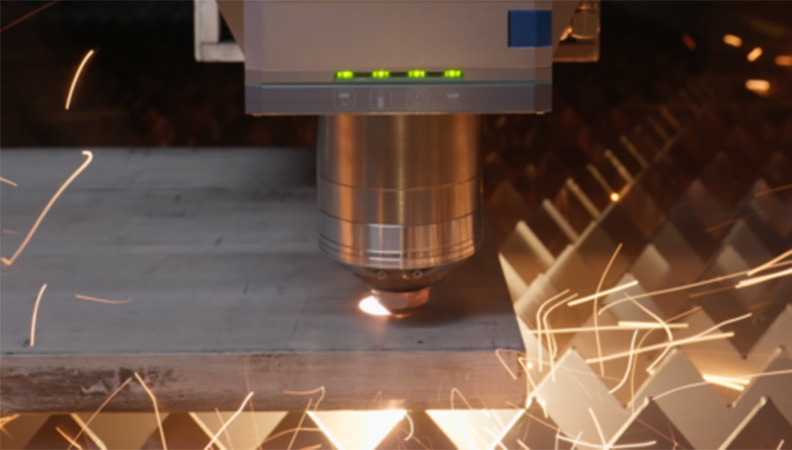

2D laser cutting: Maximum speed and precision

2D laser cutting is the leading technology for the precise processing of steel, stainless steel, aluminum and non-ferrous metals. Our solutions enable:

- Highest cutting speeds for efficient production

- Dynamic process control for optimum material utilization

- Intelligent sensor technology for reproducible quality and minimal scrap rates

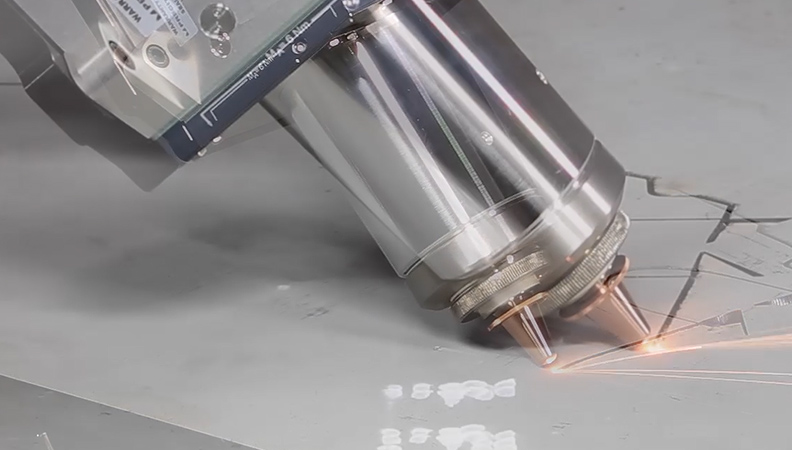

2.5D laser cutting: Bevel cutting for precise weld preparations

Bevel cutting enables the processing of material edges with angled cuts to create perfect weld seam preparations. Our technology offers:

- Precise angle cuts for optimum weld seams

- Flexible adaptation to different material thicknesses

- Maximum precision and process reliability thanks to smart sensor solutions

3D laser cutting: Flexibility for complex geometries

3D laser cutting is indispensable in the automotive and aviation industries as well as in mechanical engineering. Our technology enables:

- Processing three-dimensional components with maximum precision

- Automated adaptation to material and contour

- Reliable processes thanks to smart real-time monitoring

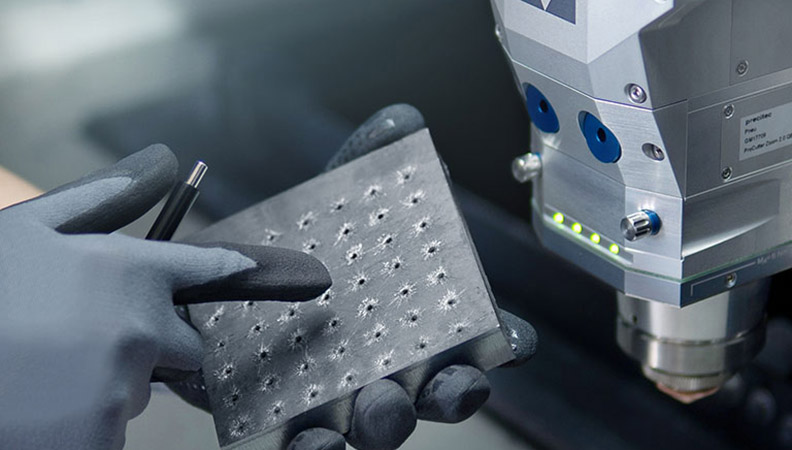

Automation & process sensors for the highest quality

Our process sensor technology monitors the cutting process in real time and ensures stable, precise and economical production. You benefit from intelligent sensor solutions:

- Continuous process monitoring for maximum cutting quality

- Early error detection to reduce rejects

- Automated adjustments for consistently high production efficiency

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-cutting/Koepfe_Ressource_768x576_01.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-cutting/UEberwachung_Ressource_768x576.jpg)