Utmost performance and precision for 2D cutting applications

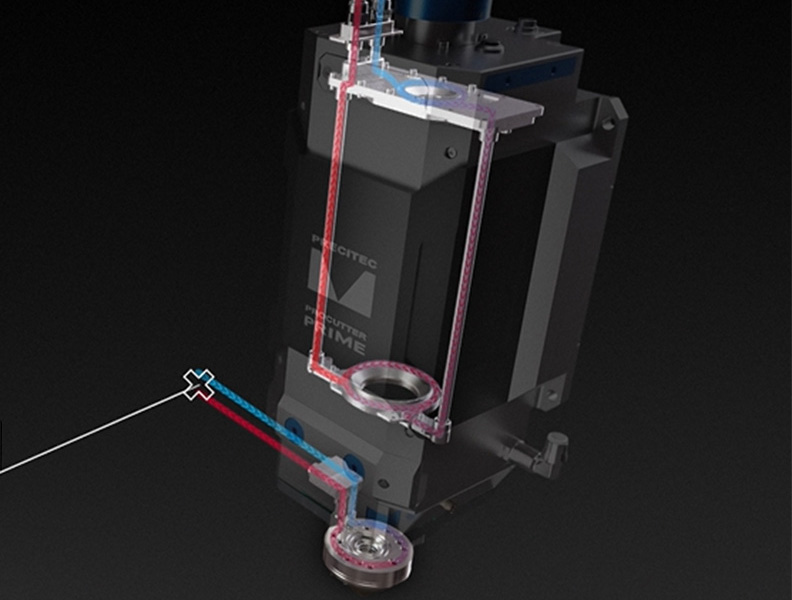

The ProCutter Prime sets new standards in efficiency and precision. Developed for machine builders with the highest demands, this cutting head with an output of up to 30 kW offers outstanding results for both thin and thick sheets. The powerful technology is the ideal choice for highly productive production environments and enables manufacturers to differentiate themselves in the market through innovation and quality.

Your advantages at a glance

Superior cutting

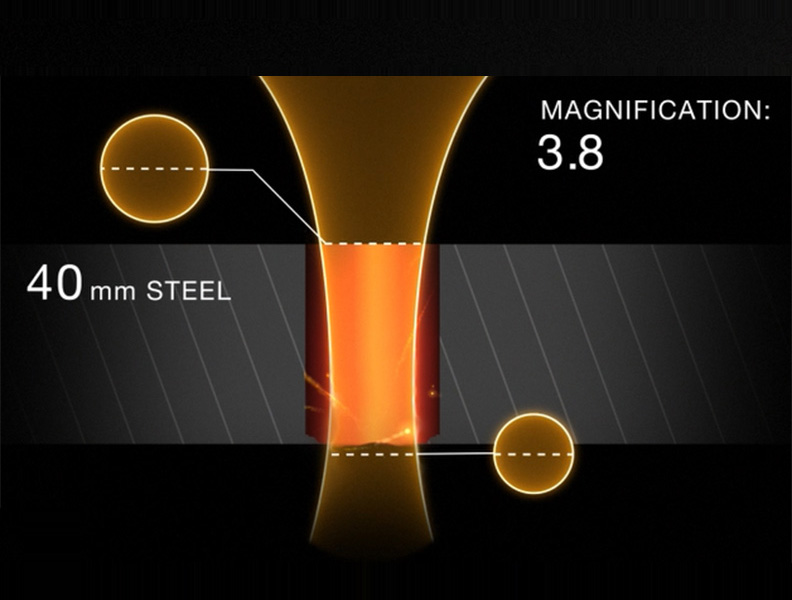

Maximum process stability is ensured by improved cooling, reliable protection against contamination and always precise focus with BeamTec technology. The variable magnification enables optimum adjustment for higher productivity and the best cutting edge quality.

Outstanding piercing performance

Thanks to variable magnification, the laser remains active at all times, ensuring shorter process times, fast and clean piercings and greater process stability. Less spatter means a longer service life for the protective glass.

Easy maintenance

Maintenance work can be carried out directly on the machine, while the quick and easy-to-learn maintenance operations reduce downtime and costs. These methods are also easy to train, which further increases efficiency.

Maximum efficiency and flexibility

The ProCutter Prime represents a new generation of laser cutting technology and offers an impressive output of up to 30 kW. With the help of the innovative zoom function for variable magnification and BeamTec technology for dynamic focus control, the cutting head enables flexible adaptation to different materials and cutting conditions. This results in increased productivity and precision when processing both thinner and thicker materials. The ProCutter Prime thus ensures maximum efficiency while simultaneously improving process speed and cutting quality.

Optimized cutting quality and process stability

The ProCutter Prime impresses with its ingenious gas flow design, which reduces turbulence in the gas flow and therefore ensures a consistently high cutting quality. This optimization is particularly advantageous when processing stainless steel and mild steel, as it results in clean cutting edges and lower reworking costs. This is complemented by comprehensive sensor monitoring, which comprises more than 35 sensors. These monitor the status of the cutting head in real time and ensure that the entire cutting process is stable and safe.

User-friendly service concept and maintenance

The service concept of the ProCutter Prime was developed so that maintenance tasks can be carried out quickly and easily directly on the machine. Thanks to the modular cassette system for optics and protective glass, replacing these components is particularly quick and uncomplicated. Access to the components is from the front of the machine, minimizing downtime and making maintenance processes efficient. This user-friendly concept helps to optimize the operation of the system in the long term and ensure high availability.

Precise laser cuts for all material thicknesses

The ProCutter Prime impresses with minimal material loss and high repeat accuracy:

- Mild steel: Cut edges with low roughness thanks to laser flame cutting with oxygen

- Stainless steel: Precise, oxide-free edges thanks to laser fusion cutting with nitrogen or compressed air

- Aluminum: Clean cuts thanks to laser fusion cutting

It processes materials up to over 70 mm and is particularly efficient with medium to thick materials (over 10 mm), but also with thin sheets. With maximum flexibility, the cutting head always delivers clean and precise results.

Technical data

- Max. laser power: 30 kW (1070 ±10 nm)

- Max. NA: 0.13

- Magnification: X1.2 to X4.0 in 0.1 steps

- Axial length: 577 mm

- Dimension: 192 x 168 mm (WxD)

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Do you still have any questions or would you like an offer? Then contact us!

Our Whitepaper on ProCutter Prime

Laser technology is evolving rapidly to maximize precision, speed and versatility. Advances such as zoom function, intelligent focus control and optimized gas control increase efficiency - especially when cutting thicker materials. At the same time, more complex manufacturing processes require more powerful and more integrated laser cutting heads.

Read our white paper to find out which innovations set the ProCutter Prime apart and how you can optimize your production processes.