Automated total solution for your laser welding

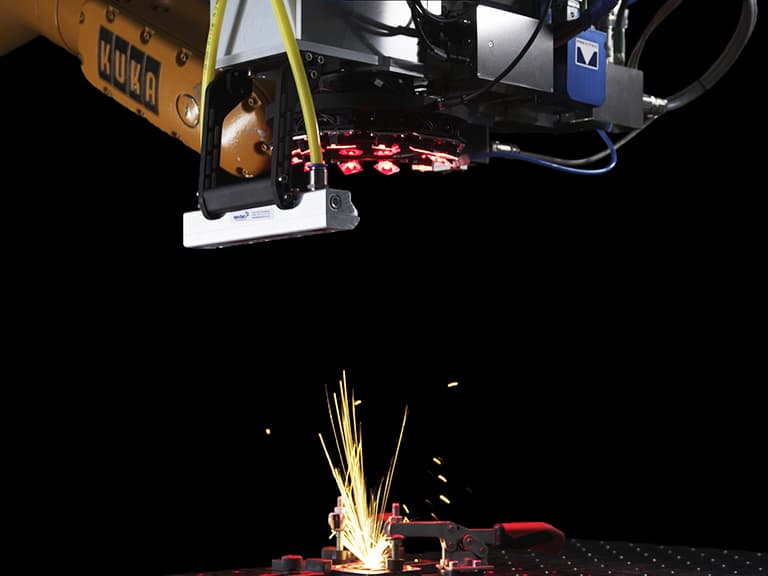

Process monitoring for series production

Precitec monitoring systems help in many areas of industrial production in 24/7 operation. The measured data recorded during the welding process are used for 100% quality control. Production errors are detected immediately and can be corrected in time. The data storage in combination with the component ID enables consistent traceability.

Process monitoring for series production

- Monitoring of quality fluctuations

- Increasing the output

- 100% traceability and transparency

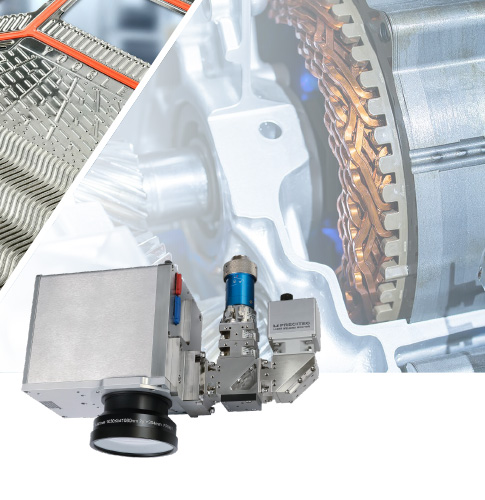

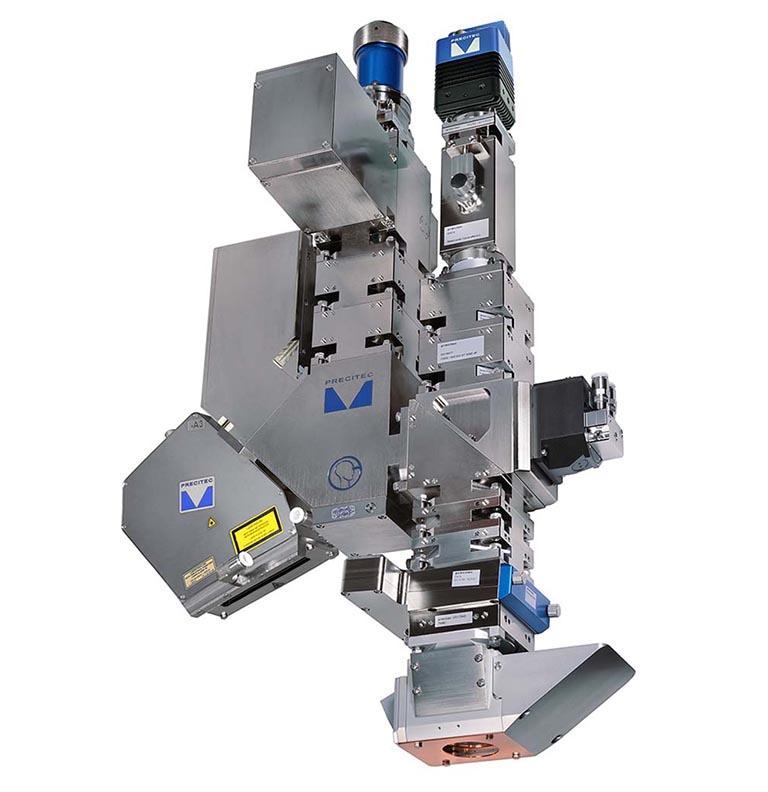

Sophisticated laser welding processes with filler wire

- Camera-based seam tracking with AI support

- Adaptive gap bridging

- Ideal for 24/7 operation

- Full transparency thanks to data interface

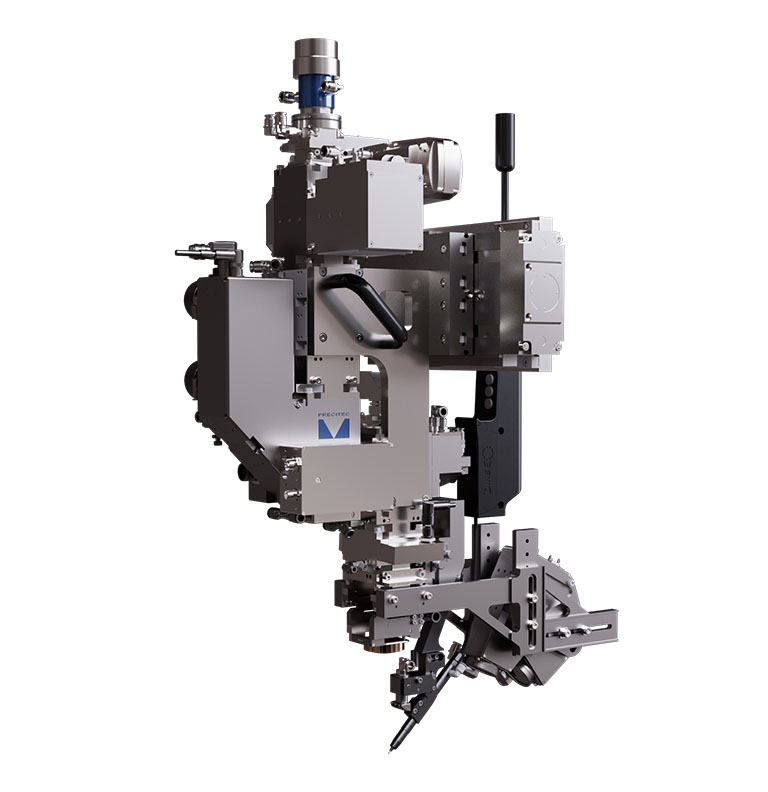

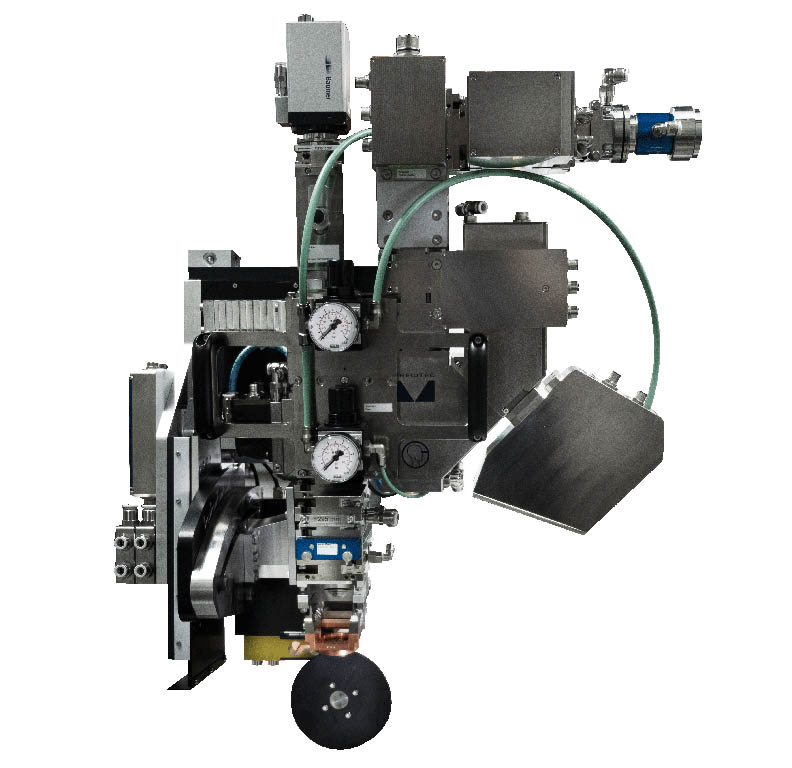

Intelligent laser welding system with pressure roller

Less set-up work

Creation of dense, high-quality weld seams

Optimizes overlap and fillet welds

Automated total solution for your welding process

- Tracking of the seam, beam guidance and shaping as well as online quality control

- Optimal for 24/7 operation

- 100 % documentation and networking

Monitoring and control of your welding depth

- Highly accurate measurement in real time

- Avoidance of rework and rejects

- 100 % documentation, transparency, and traceability

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-welding/Koepfe_Ressource_768x576_01.jpg)