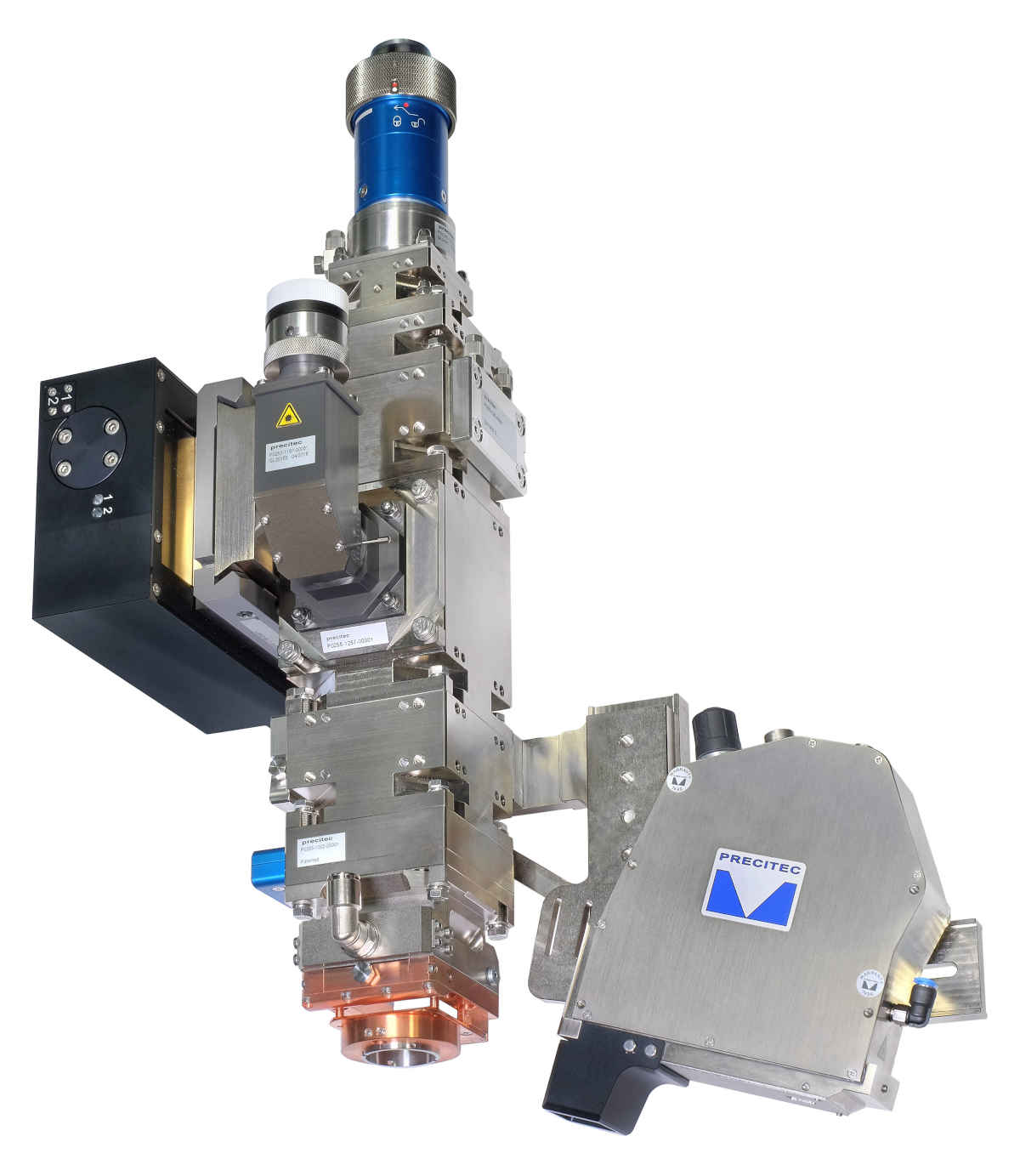

High-precision measurement of the component position and positioning of the welding unit

The WeldMaster 4.0 Track measures the component position in the immediate vicinity of the welding position contactlessly, quickly, and with high precision. The joining position and gap are detected and used for high precision control of the welding unit. The intelligent and automated seam tracking detects different joining geometries such as a butt joint, zero gap, fillet weld in lap joint and T-joint.

Advantages

- Reproducible quality of laser welding

Laser welding always achieves the best process result due to reliable seam finding and position control. Component tolerances are detected and deviating joining positions are measured. Thus you get automated, reproducible laser welding processes of the highest quality. - Avoidance of rework and scrap

Due to the fast and high-precision measurement of the joining steels and the regulation of the beam position, you are 100% in the correct welding position. The seam is thus optimally executed even with changing components or different material thicknesses and batches. The WeldMaster 4.0 Track thus makes a decisive contribution to increasing productivity.

Technical data

- Fieldbus and analog interfaces for controlling 2 axes

- Standard interfaces to Precitec welding heads and axes

- Customer-specific interfaces to external axes

- Processing of encoder signals

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Our service for your productivity

Commissioning Laser Technology

Learn more

Training Laser Technology

Learn more

Maintenance Laser Technology

Learn more

Spare Parts Laser Technology

Learn more

Repair Laser Technology

Learn more

Hotline Laser Technology

Learn more