Precise non-contact inspection in display manufacturing

Optical 3D metrology for consumer electronics

The coated and extremely hardened screen glass in smartphones or tablets has to be manufactured to the highest highest quality standards. Any scratches or cracks must be detected before installation and the flatness of the display glass measured with pinpoint accuracy.

Precitec has exactly the right non-contact optical metrology required to carry out these challenging tasks at high speed and with utmost precision.

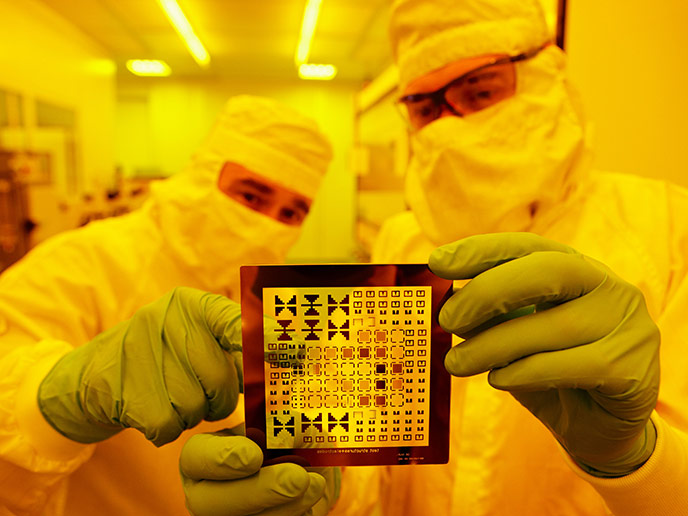

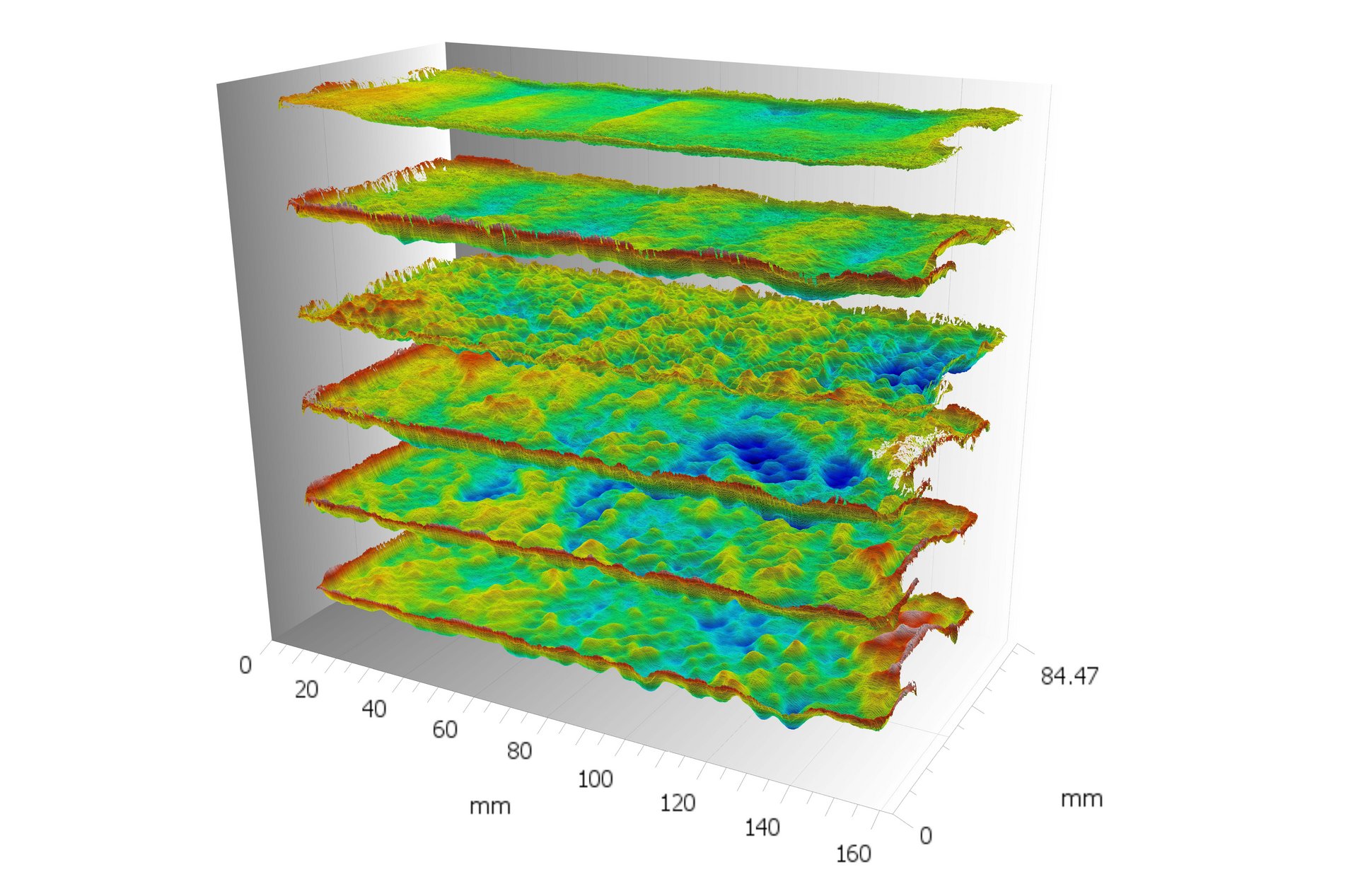

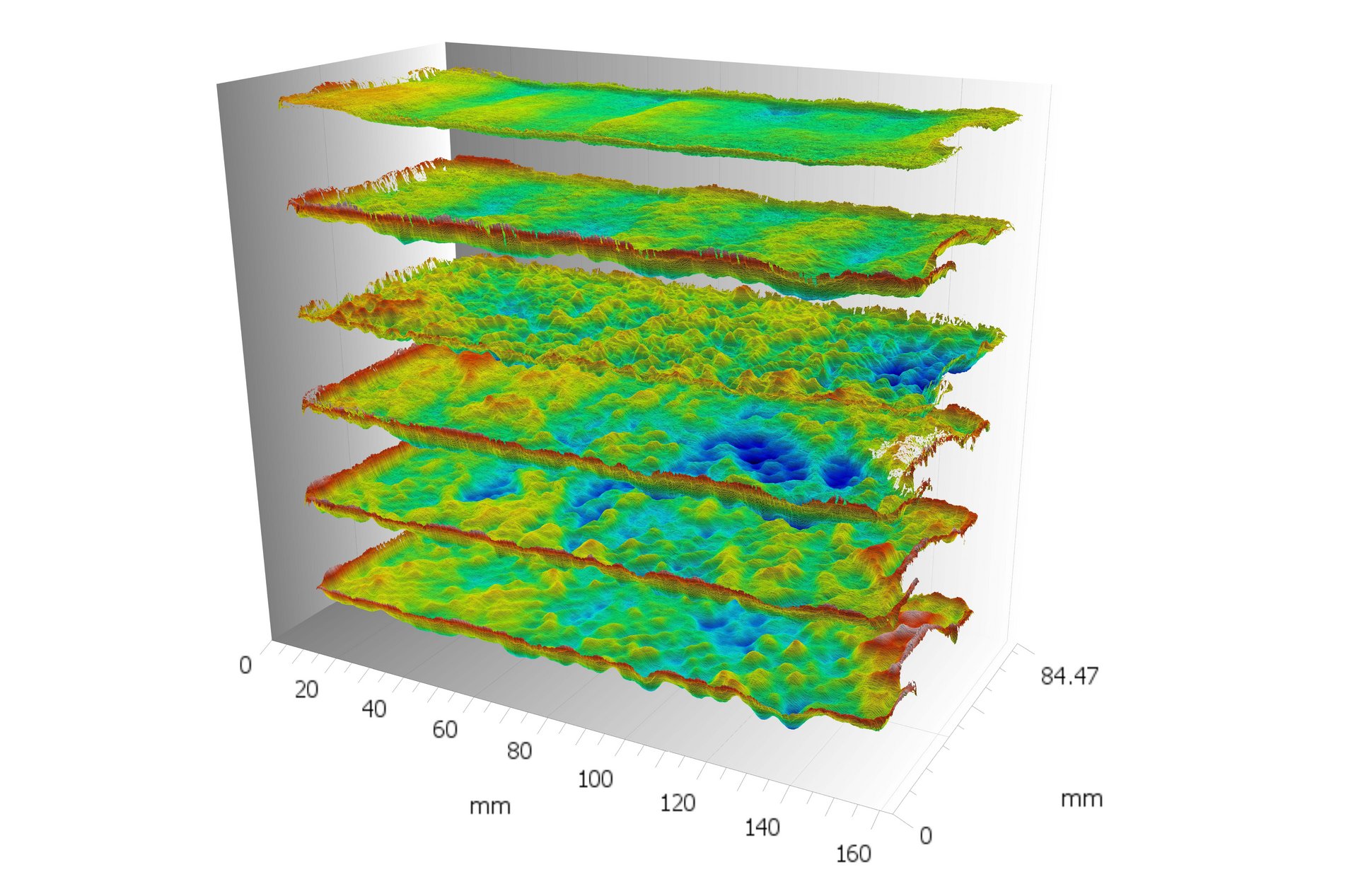

Display layer stack inspection

To meet the high-quality standards expected of the latest display generation, it is essential to reliably and repeatably detect display layer defects under serial production conditions. The Flying Spot Scanner family – and in particular the FSS 80 – is perfectly suited for this task, including the control of display layer stacks as well as thickness and flatness measurements. With the FSS 80, precise measurements of displays used in watches, tablets, wearables, TV screens, and smartphones – including those with foldable and flexible designs – can be carried out at high speed and with great repeatability.

Detailed information on quality inspection of foldable displays is available in our white paper, which can be requested here.

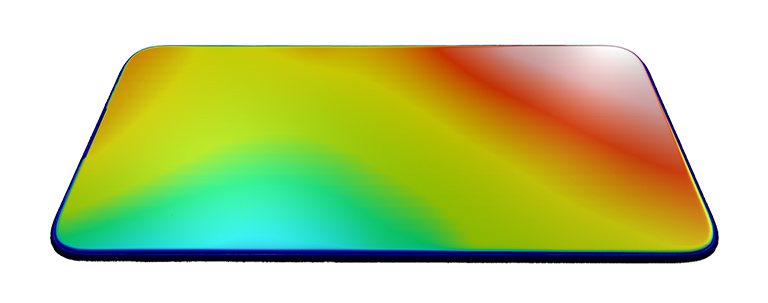

Flatness inspection of display glass

The display has a decisive influence on the look and haptics of a smartphone. That is why the flatness of the display glass has to be checked inline during the production process.

The Flying Spot Scanner enables inline measurements at various predefined locations without the need to scan the whole display surface.

Thanks to its high repeatability to within a few µm, the Flying Spot Scanner is perfectly suited to conducting such inspections on samples passing by at up to 3 m/s, even with the protective film attached.

For more details click on the Flying Spot Scanner product video.

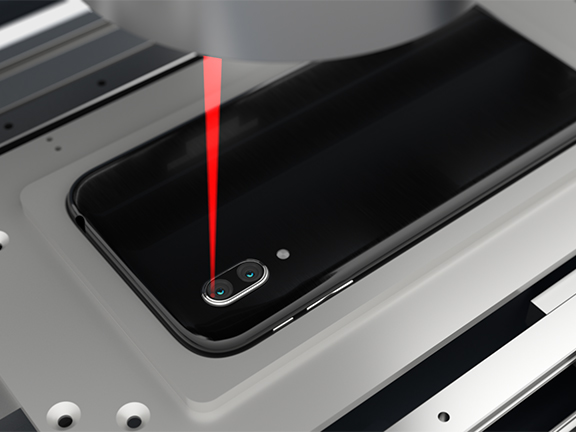

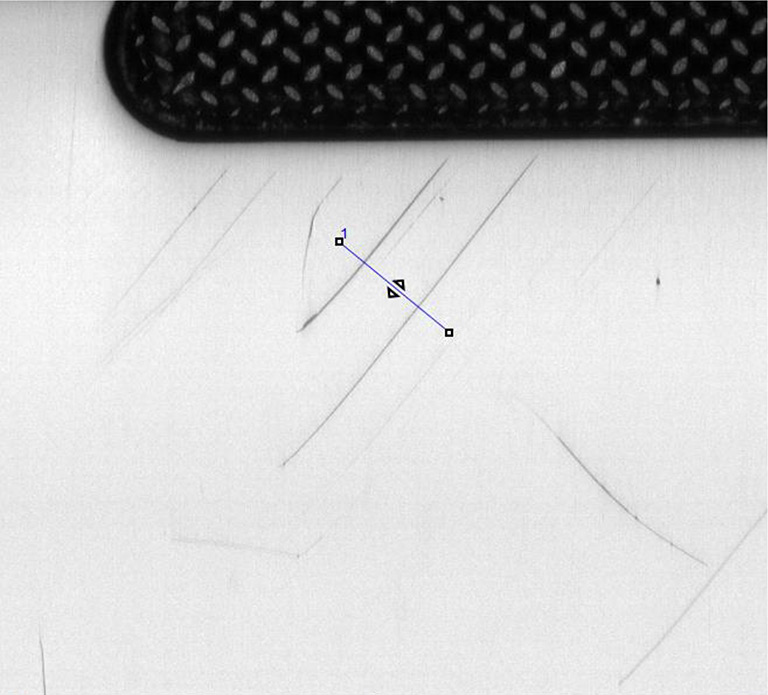

Scratch and crack detection

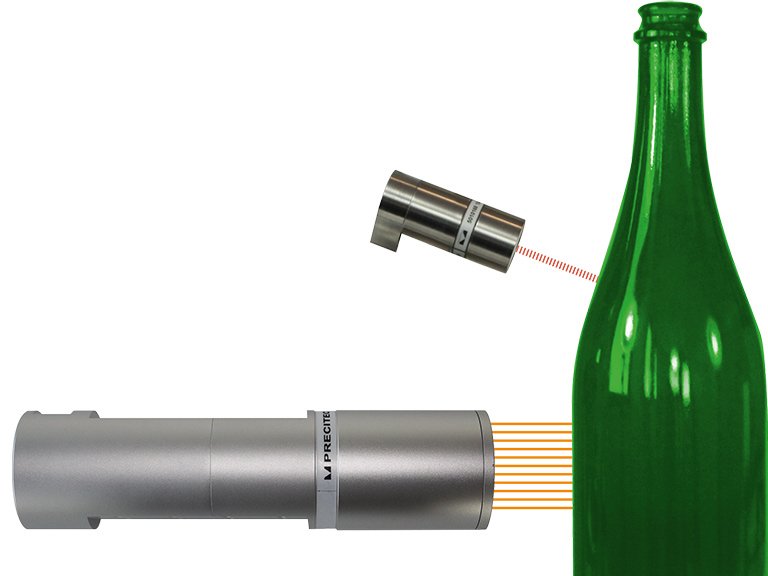

Display glass may have scratches of a few µm and defects up to 100 µm in size. The ultra-fast CHRocodile CVC chromatic line scan camera uses chromatic confocal technology to detect scratches only a few µm wide.

This metrology principle enables an outstanding depth of field resulting in high tolerance for the sample position with respect to the focal plane. This high-speed camera measures inline in a very short cycle time with a sample rate of up to 140 kHz.

More information about the CHRocodile CVC in the product link.

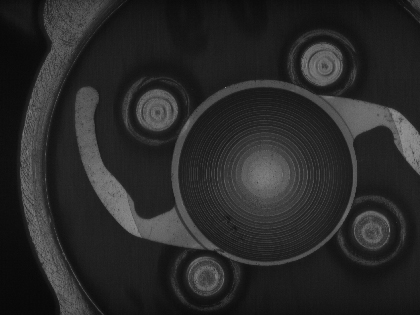

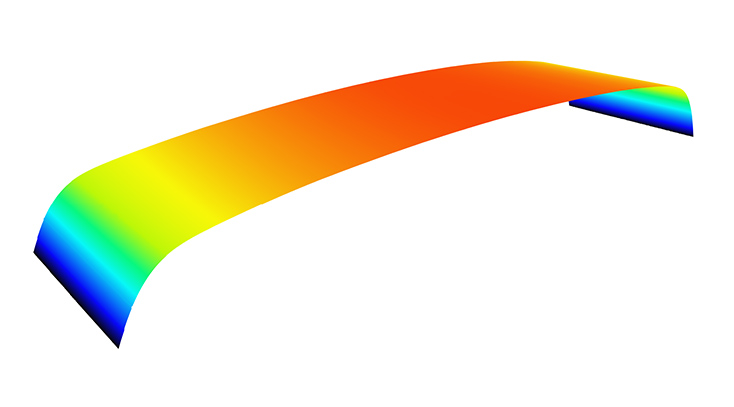

Display curvature inspection

The display curvature of a smartphone’s front and back glass is essential for the overall haptics of the phone. The highest quality standards have to be fulfilled, especially at the gap between glass and the housing.

With its high angle acceptance the CHRocodile CLS is particularly suited for this task. Besides, this device can measure on all kinds of surface materials, e.g. reflective glass, various metals as well as on light, dark or colored backgrounds.

The high lateral resolution – to within as little as 1 µm – enables step heights and gap distances to be measured with utmost precision.

Have a look at the CHRocodile CLS HS product video to learn more.

In the consumer electronics field we have a lot more to offer ...

...as multiple production steps are commonplace here. Our laser welding and cutting technology also supports fully automated production systems in meeting the highest quality requirements.

Take a look at how you can benefit from Precitec's comprehensive laser welding & quality control solutions!