Optical metrology for consumer electronics

Quality inspection with utmost precision

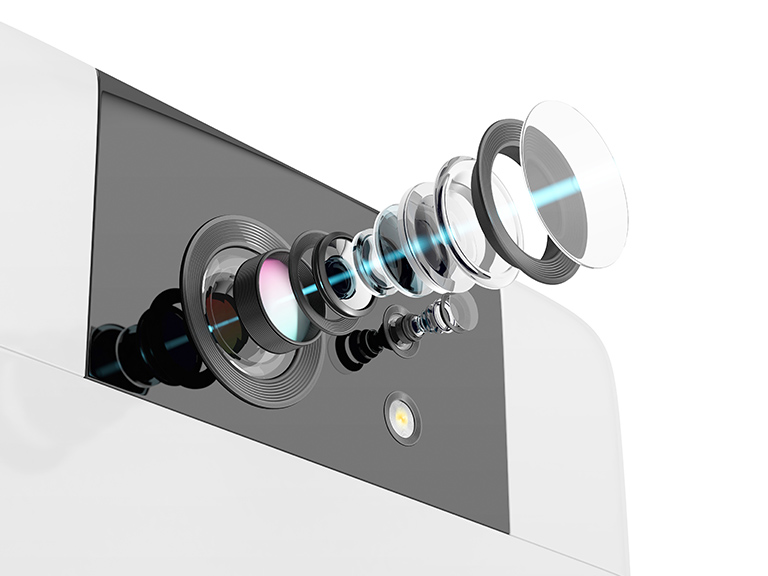

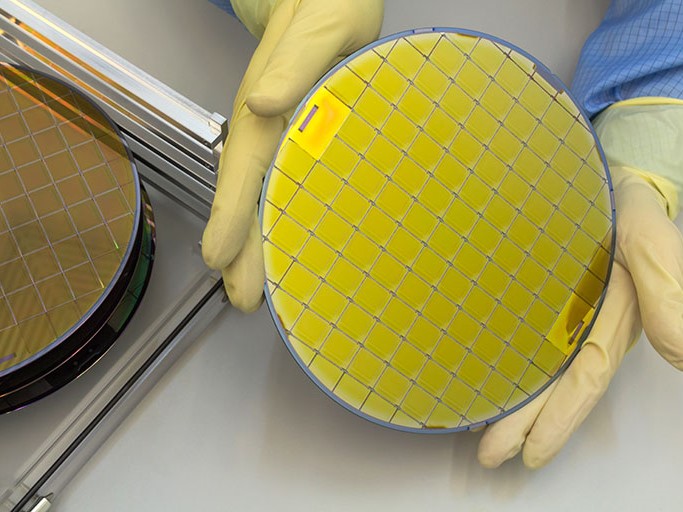

Utmost precision is required in manufacturing consumer electronics products, such as mobile phones, tablets and displays. The interplay of a wide variety of materials and the complex geometries of these products are the key quality assurance challenges. 3D metrology helps the consumer electronics industry to master these challenges.

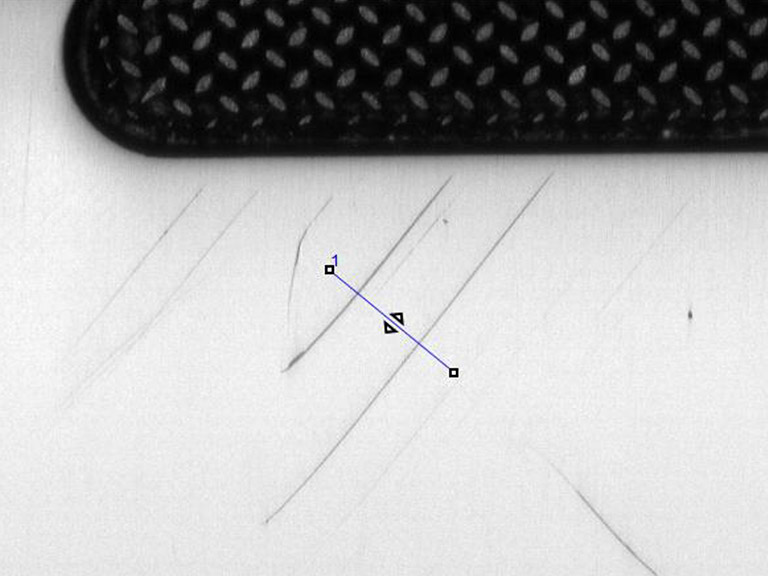

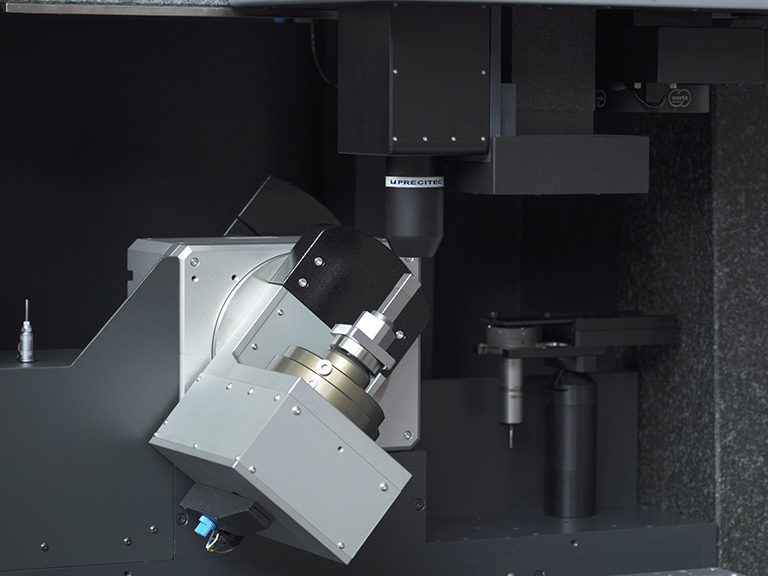

By using our non-contact optical sensors you can measure the gap between the glass and housing of a smartphone and the flatness of display glass and inspect step heights, edges and PCB coatings to within a few µm.

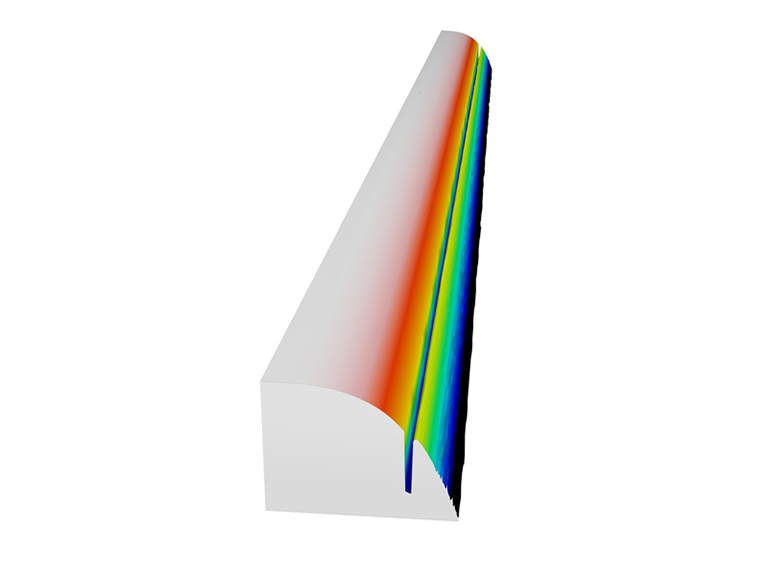

As Precitec’s CHRocodile CLS chromatic confocal line sensor scans with up to 192 simultaneous measuring points, it covers much larger surfaces than a conventional point sensor in the same time. The CHRocodile 2 IT series carries out thickness measurements of layers as thin as 0.6 µm at a measuring rate of up to 70 kHz. By combining the IT series with Precitec’s Flying Spot Scanner, you can measure the distinct profiles of relevant components along predefined scan paths in a significantly shorter overall time.

For mass production lines in the consumer electronics industry, it is not just high precision and speed that are required of optical sensors but also the ability to measure inline. That is why the products in the CHRocodile Line Sensor portfolio are the ideal solution for each specific task in the electronics industry. With three specialized sensors, each tailored to distinct measuring tasks, these superior solutions provide companies with a significant productivity advantage.

In the consumer electronics field we have a lot more to offer …

... as multiple production steps are commonplace here. Our laser welding and cutting technology also supports fully automated production systems in meeting the highest quality requirements.

Take a look at how you can benefit from Precitec's comprehensive laser welding & quality control solutions!